For modern manufacturers, the increasing demand for high quality, complex, accurate components means they need to ensure fast, accurate and repeatable measurements of every component.

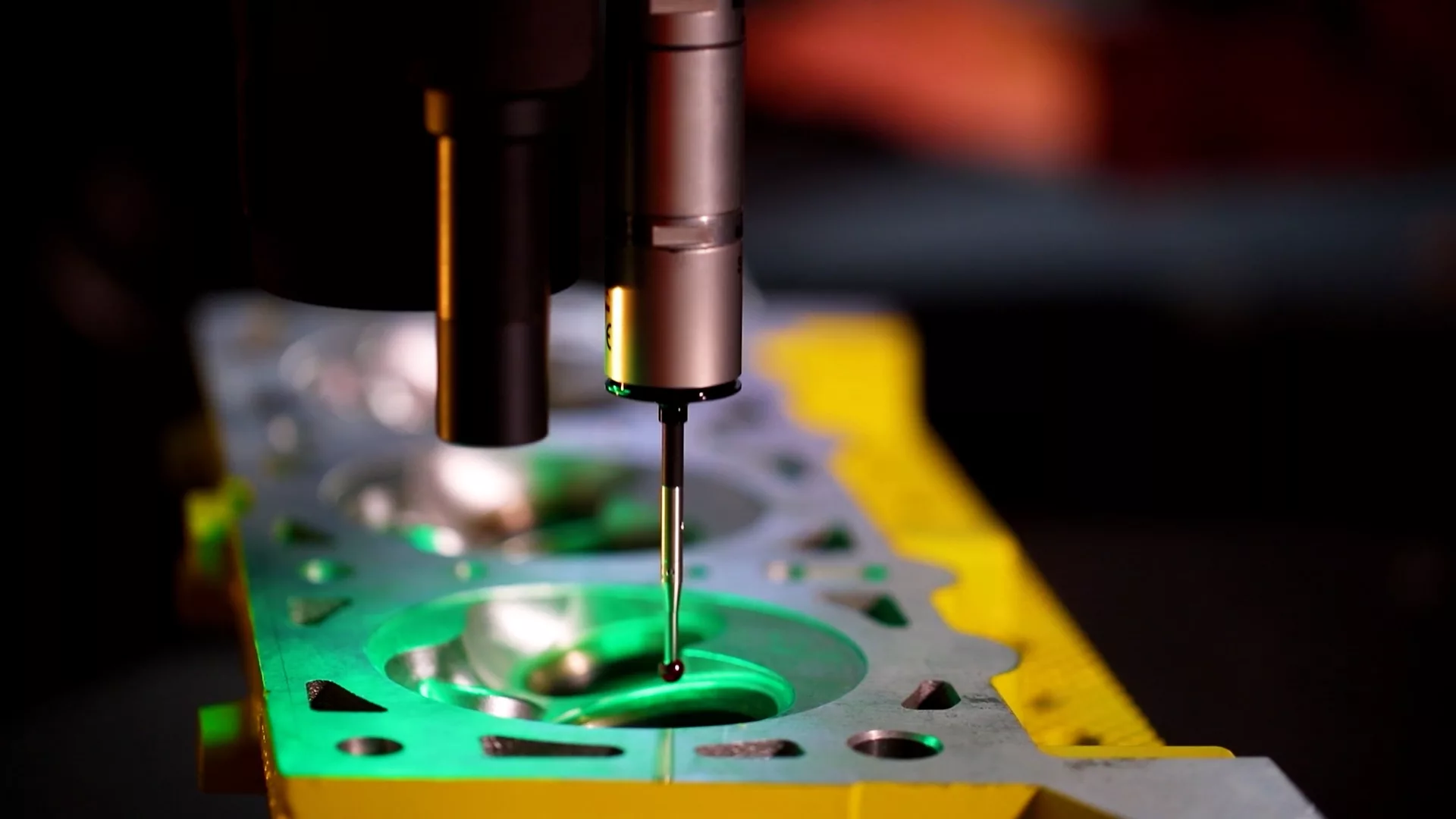

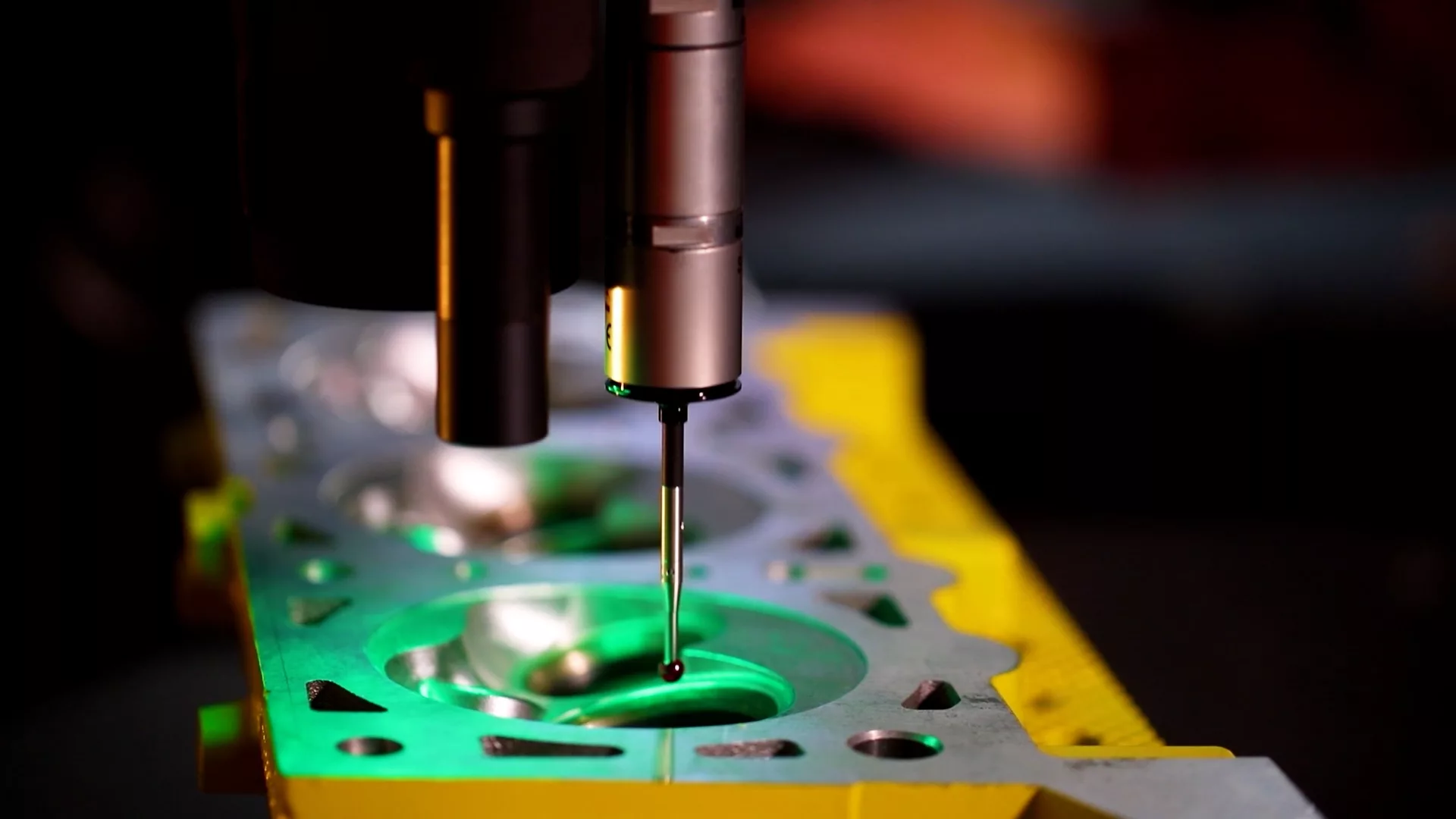

Traditionally, component measurement would require the use of multiple devices, including hand gauges, CMM’s and shadowgraphs. OGP UK’s best-in-class multi-sensor measurement systems combines all of these capabilities into a single system, providing unrivalled speed, accuracy and performance in the quality control of manufactured parts and components. It allows manufacturers to accelerate their inspections, without sacrificing quality or accuracy.

How you can measure a part up to 100x faster with OGP multi-sensor measurement

Singular machine

- OGP multi-sensor measurement machines include all sensors on a singular machine, saving not only valuable floorspace, but minimising set-up and changeover times compared to traditional methods which require multiple devices and setups.

Single programme

- All of the sensors (lasers, optics, touch probes) can be utilised in a single, repeatable inspection programme, capturing all the necessary data in a fraction of the time, compared to inconsistent, time-consuming manual methods.

Automated reporting

- OGP state-of-the-art software generates instant reports within minutes of the inspection. This ensures accurate, reliable and consistent data at the touch of a button to save operators hours of manual data entry time and remove human error.