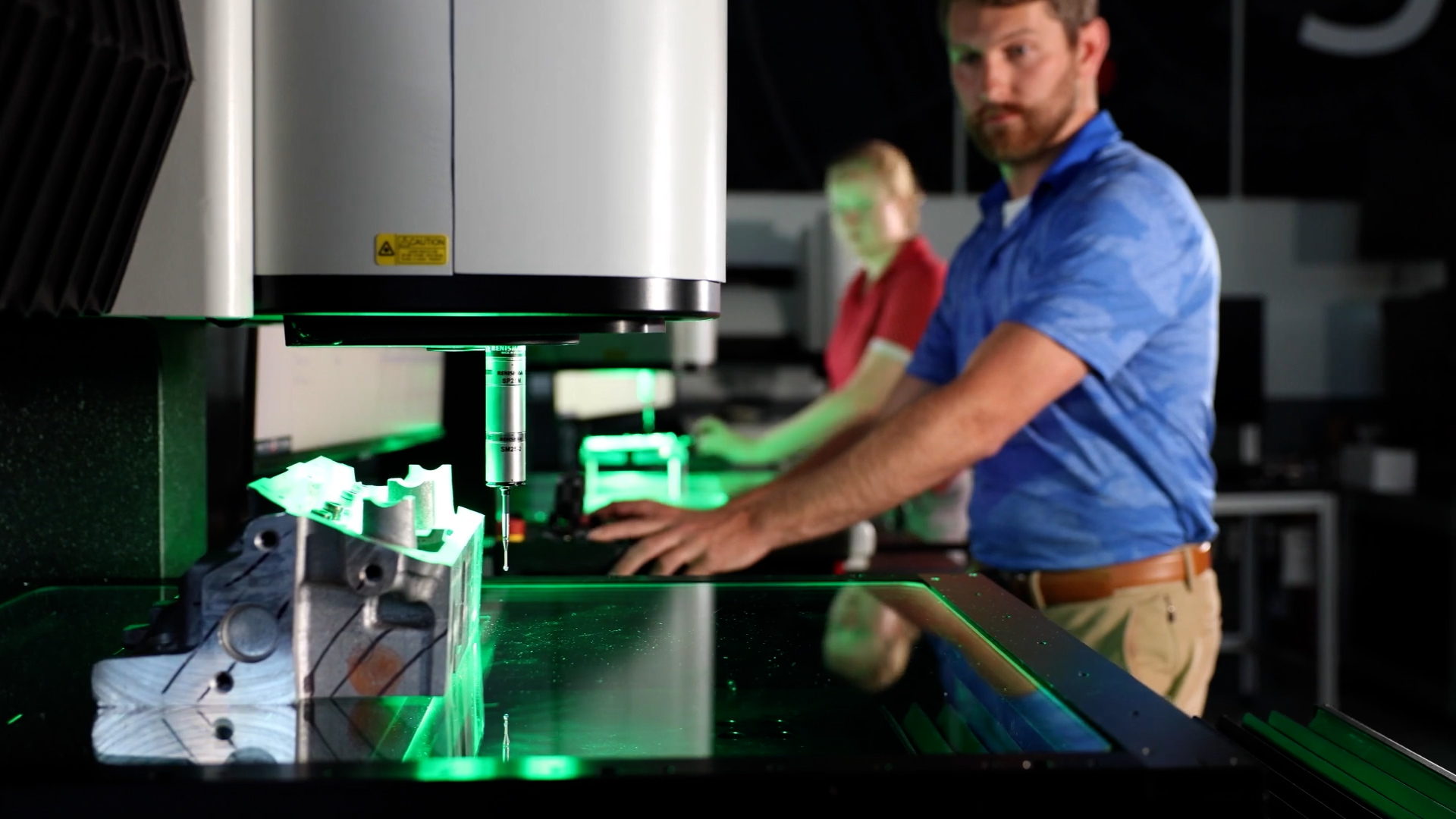

The Benefits of Multi-sensor Metrology for Manufacturing Quality Control

In the fast-paced world of modern manufacturing, ensuring product quality is non-negotiable. Multi-sensor metrology has emerged as a game-changing solution for manufacturing quality control, offering