In the fast-paced world of modern manufacturing, ensuring product quality is non-negotiable.

Multi-sensor metrology has emerged as a game-changing solution for manufacturing quality control, offering unmatched precision and efficiency.

This article explores how multi-sensor technology enhances manufacturing processes by boosting accuracy, reducing inspection times and streamlining operations.

Manufacturing Quality Control

Manufacturing quality control is essential for maintaining high standards, ensuring products meet specifications and avoiding costly errors.

Traditional inspection methods often rely on single-sensor systems, which can be time-consuming and limited in their scope.

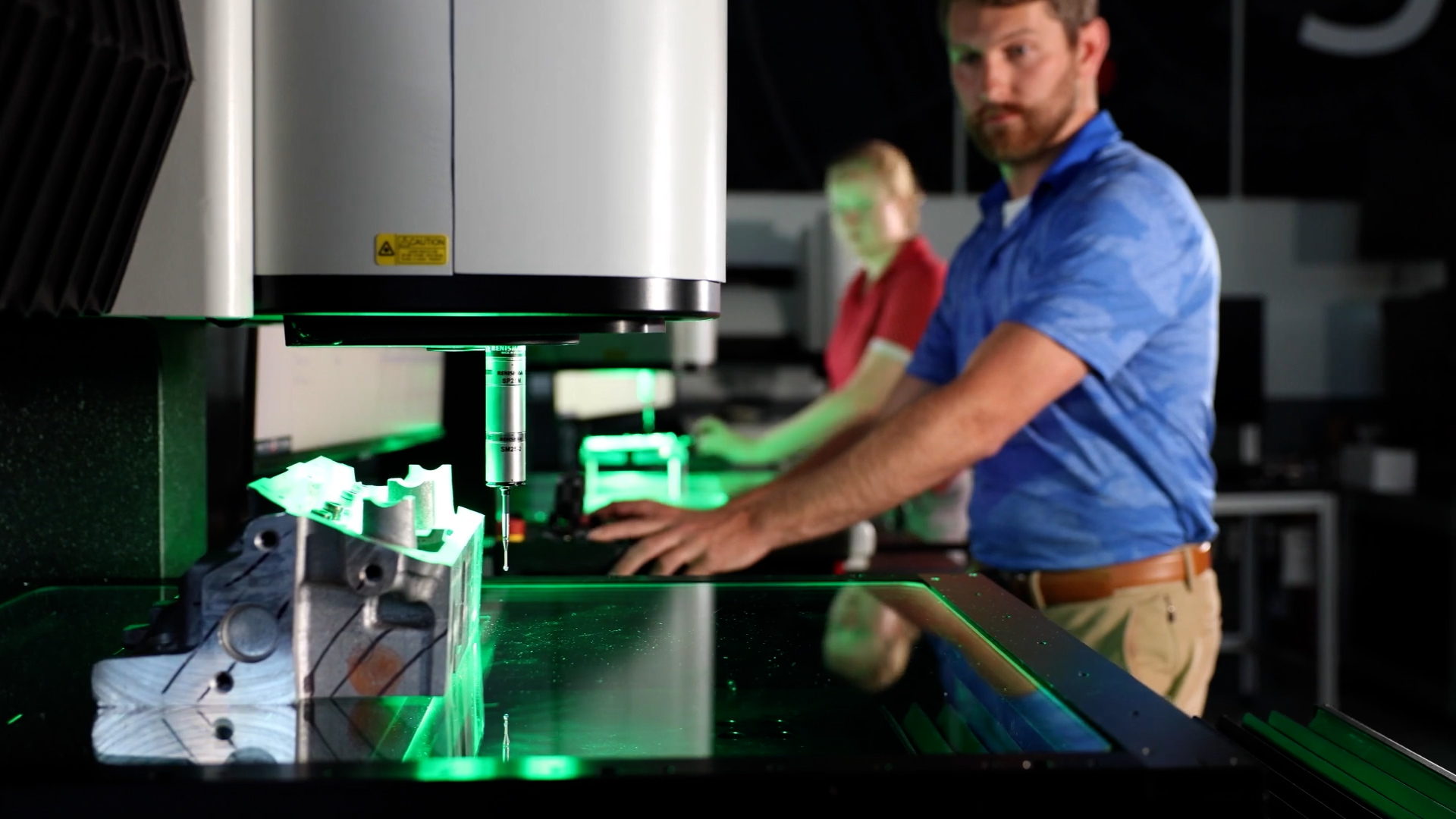

Multi-sensor metrology, however, integrates multiple sensors — optical, laser and tactile — into one system. This allows manufacturers to perform comprehensive inspections without the need for multiple set ups, providing a faster and more reliable way to validate component accuracy.

Benefits

Adopting multi-sensor metrology for manufacturing quality control brings a host of benefits, helping companies maintain competitive advantages and improve production workflows. Let’s dive into the key advantages.

Accuracy

Multi-sensor systems capture data from different angles and use various technologies to measure complex geometries with extreme precision.

By combining optical sensors for surface details, laser scanners for 3D measurements and tactile probes for hidden features, manufacturers can achieve accurate and repeatable results.

With multi-sensor metrology, even intricate components with tight tolerances are measured with confidence, ensuring products meet exact design specifications.

Reduced Inspection Times

One of the stand-out advantages of multi-sensor metrology is its ability to reduce inspection times. Traditional methods often require multiple instruments or separate set ups to gather comprehensive data. Multi-sensor systems, however, collect all necessary measurements in a single, automated process.

By consolidating measurement routines, manufacturers can cut inspection times dramatically — improving throughput without sacrificing quality.

Process Efficiency

Efficiency is crucial in manufacturing and multi-sensor metrology plays a vital role in streamlining quality control. Automated measurements, combined with advanced metrology software like ZONE3, enable seamless data analysis and reporting.

Manufacturers can integrate multi-sensor technology directly into their production lines, allowing for real-time monitoring and quicker decision-making. This reduces bottlenecks, minimises rework and enhances overall process efficiency.

Embrace Multi-sensor Metrology for Superior Quality Control

Incorporating multi-sensor metrology into manufacturing quality control processes not only improves accuracy and reduces inspection times but also boosts operational efficiency.

To stay ahead in today’s competitive landscape, manufacturers must adopt innovative solutions that enhance productivity and product quality.

Discover how OGP UK’s multi-sensor metrology solutions can revolutionise your quality control processes and drive manufacturing excellence. Contact OGP UK today.