Dual Rotary Indexers

Mount two rotary indexers together with their axes perpendicular to one another to add two more axes of part positioning.

Automatic part rotation on multiple axes

Several combinations of rotaries can be configured, depending on the application and the available measurement envelope of the machine.

The part under inspection is attached to the secondary rotary, which is mounted to the primary rotary. The part can be rotated in two different axes to provide a means of bringing features with compound angles into the line of sight of the optical sensor axis and within the reach of available laser sensors or touch probes for measurement.

MTR / MSR

Combine MTR and MSR indexers on a benchtop measuring machine to provide rotary motions in two perpendicular axes. The MTR is used as the primary rotary in this configuration, making this set up ideal for positioning complex, lightweight parts into separate views.

HDR / HDR

The dual HDR configuration has a 30 kg-cm load capacity, allowing for rotation of larger parts. With a high rotational position accuracy of +5 arc seconds, dual HDRs can rotate heavy parts while maintaining optimum positional accuracy.

HDR / MTR

Using HDR and MTR indexers during a measurement routine allows for the rotation of parts into view with higher accuracy. The HDR is used as the primary rotary in a configuration that allows for complex measurements on small parts.

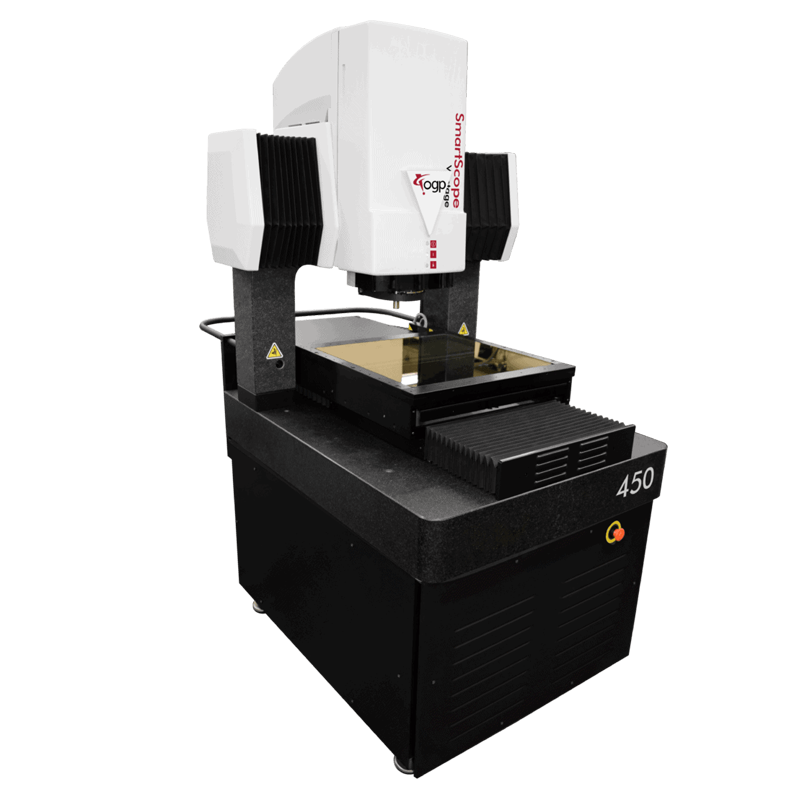

Compatible machines

Book your

in-person demo

Book a free demo at our Advanced Innovation Centre where you can see Dual Rotary Indexers in action to witness how it can be incorporated into measurement routines.

Download the full specifications

Get the full technical data on Dual Rotary Indexers today. Discover the key data points, applications and technical specifications by downloading the brochure.