-

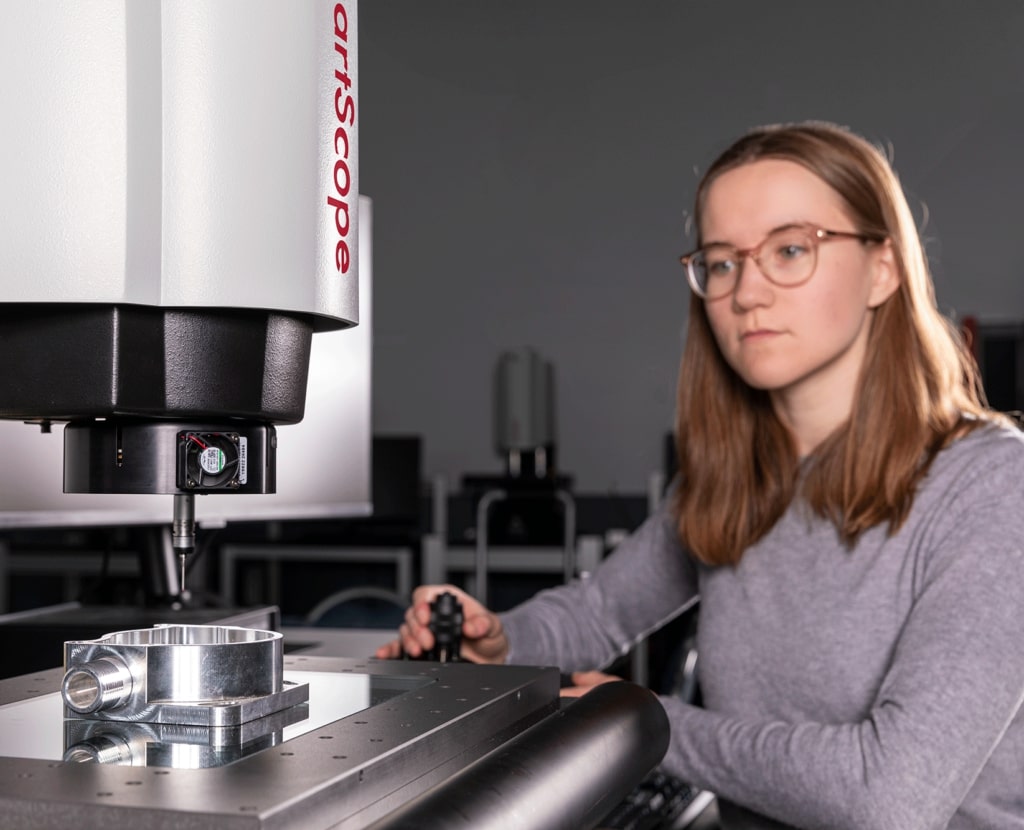

Measurement Systems

Our full range of measurement systems ensure that we can deliver the right solutions for all your measurement needs.

SmartScope Vantage

The multi-sensor measurement range that integrates superior optical performance into your manufacturing processes by delivering the highest standard of accuracy, speed and repeatability.

SmartScope SP

Designed for optimum scanning probe performance, the SP range combines a wide-field objective lens, digital zoom, and five megapixel monochrome digital camera to ensure accurate imaging at all zoom levels.

SmartScope CNC

The all-in-one multi-sensor measurement system, built to handle a wide variety of measurement requirements. The CNC range is the best choice for automatic, general purpose, multi-sensor coordinate measuring.

SmartScope E-Series

The E-Series provides benchtop, multi-sensor measurement solutions with high-resolution optics and advanced video detection, allowing fast, versatile and accurate part measurements.

SmartScope ZIP

The ZIP range provides superior optical performance and a range of machine travels to deliver reliable performance, with multiple light sources illuminating the toughest measurement challenges.

SprintMVP

Measure a broad range of parts with this range of fully-automatic 3-axis dimensional measurement systems, offering multi-sensor, non-contact video measurement capabilities.

ShapeGrabber

Laser scanning systems that deliver fast, accurate and automated 3D measurements, ideal for measuring complex shapes such as moulded plastics, castings, stampings and machined parts.

SNAP

Designed to measure small, intricate parts directly on the shopfloor, in the lab or as part of an automated work cell. The SNAP range is easy to implement into any manufacturing setting.

View

A high performance, fixed optical range of measurement systems that are engineered for critical dimensional measurements and optimal accuracy for a broad range of parts.

Fusion

Fusion systems are innovative, high-speed, 3D multi-sensor measurement systems that combine an exceptional large field-of-view optical system with multi-sensor flexibility.

FlexPoint

A new generation of multi-sensor coordinate measuring machines, FlexPoint offers a unique combination of sensors, and CAD-based programming, to solve a wide variety of dimensional measurement problems.

-

Sensors

Add more measurement functionality to your machine with additional sensors, increasing your inspection potential with probes, lasers and rotaries.

-

Discover the measurement software you need to control, monitor, display and report on every aspect of the measuring process. Discover the full capabilities of ZONE3 and the power of Prolink SPC software today.

Prolink offers an entire suite of software solutions to address and automate the data collection and quality analysis tasks performed throughout any organisation, complementing existing software. -

Resources

Explore how multi-sensor measurement can aid various industries and applications. Access news, downloads, customer stories and support, as well as training and service information to achieve your measurement goals.Discover

The latest eBooks, brochures and more to expand your multi-sensor measurement knowledge.

Applications

Discover and download all of our recent accreditations

We make it easy to trade in your old measurement system for a new OGP model.

Main Menu