Measurement solutions for medical devices

OGP measurement for medical

devices

Sub-micron precision.

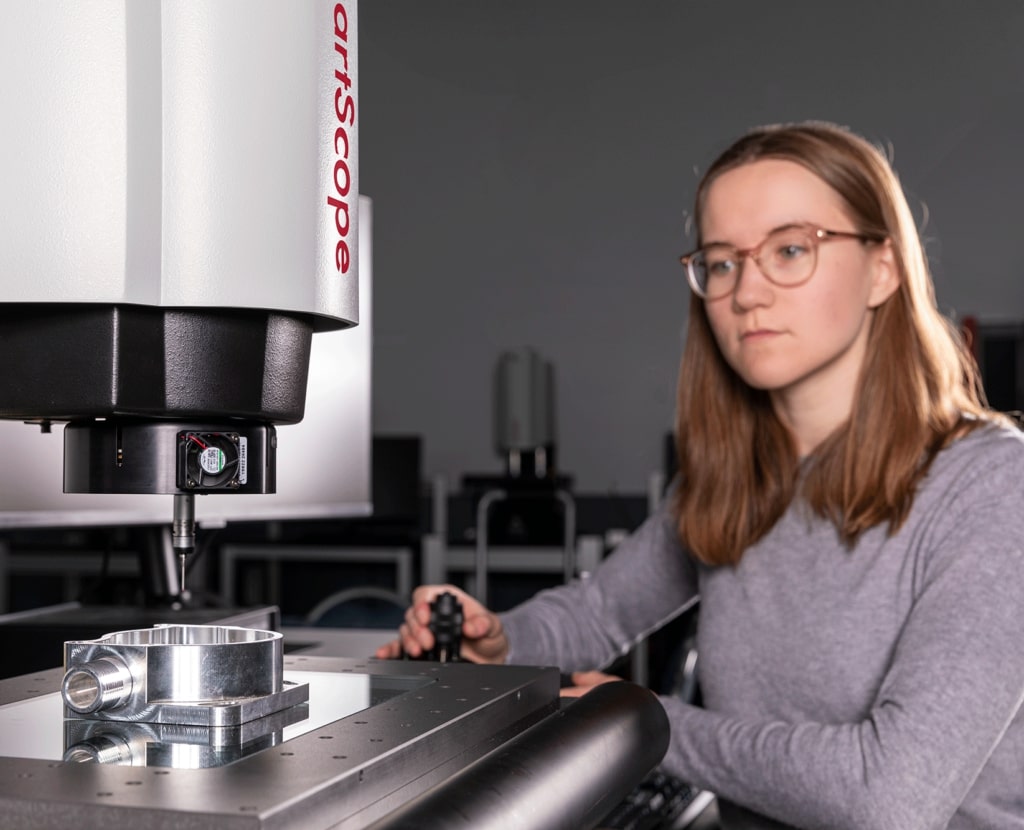

The medical industry is fast moving into an era of autonomy, reducing dependence on skilled labour to inspect critical parts for use within the human body. Now the demands placed on high-quality, high-precision parts created at sub-micron level tolerances are in focus, so too is the quality control process. At OGP UK, we supply world-class industrial metrology machining for medical-grade use making inspection fast, reliable and repeatable.

Why use multi-sensor measurement for medical devices?

Avoid part damage

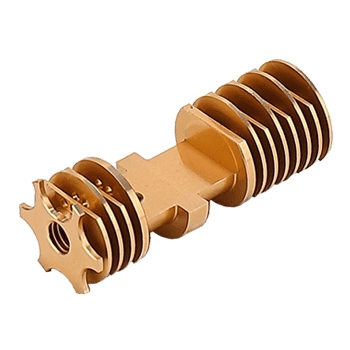

Medical devices can be delicate or sensitive, and non-contact measurement prevents parts from being damaged or deformed as they may do with traditional contact measurement techniques.

Fast measurements

Quickly scan or capture data from the entire surface of the part, allowing for rapid and efficient measurement. This is especially advantageous when dealing with complex or intricate medical devices.

Accuracy & precision

Capture fine details and minute features ensuring precise measurements of dimensions, surface profiles or geometric characteristics, resulting in more reliable and repeatable measurements.

Critical quality

Due to the specialised nature in form and function of medical devices and their component parts, they can be extremely small, such as the parts that form a middle ear prostheses for ENT (ear, nose and throat) applications. Medical device parts are often made to extremely strict tolerances and so measurement systems that characterise these medical devices must be capable of high precision, often to the sub-micron level.

Conquer your measurement challenges

OGP multi-sensor measuring machines are designed to withstand the challenges of everyday measuring. No matter the challenge your team faces, OGP UK experts are on-hand to find the best means of measuring your parts.

Get in touch

Get in touch with an expert today. Discover the full power of multi-sensor measurement to save you time and money with your inspection routines.

Improve the consistency and accuracy of your measurements to create better products. Get in touch today to discover more.