Measurement solutions for the consumer product industry

OGP

measurement in consumer

products

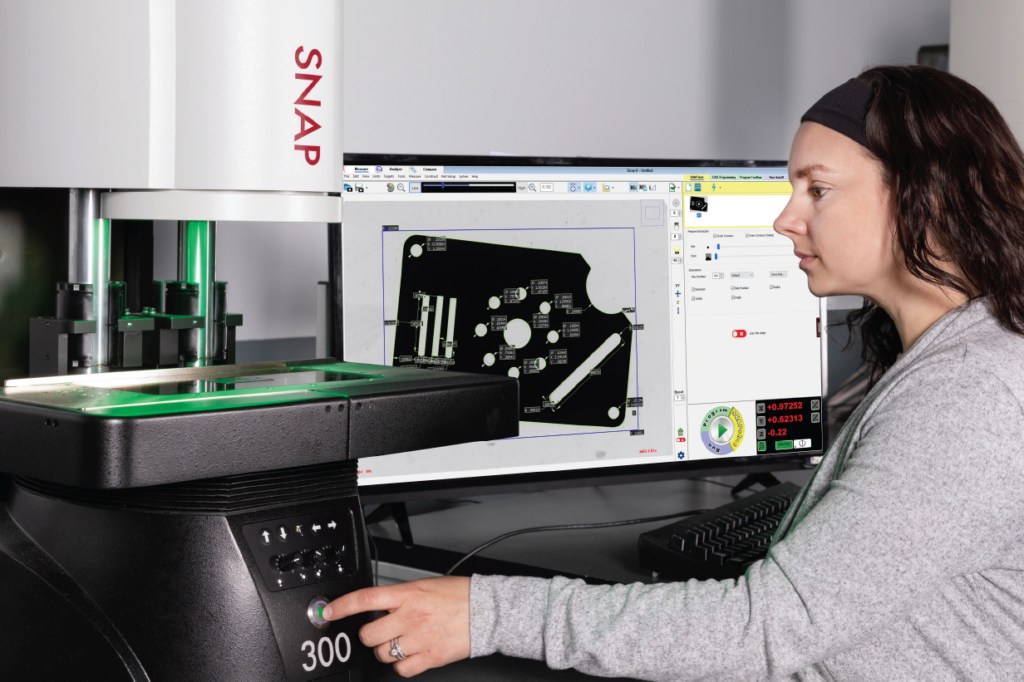

Essential to every stage of the manufacturing process, reliable inspection can save time and money.

Both for first article inspection of prototypes and for final inspection and reverse engineering, multi sensor metrology is designed to assess and validate design integrity from end to end.

Why use multi-sensor measurement for consumer products?

Enhanced accuracy

Combine data from multiple sensors for a more accurate and reliable measurement. This improved accuracy helps ensure that consumer products meet quality standards and perform as expected.

Comprehensive measurement

Consumer products often have complex geometries and a variety of features that require precise measurement. OGP multi-sensor systems can combine optical, touch-probe, and laser sensors to capture dimensional, surface and form data.

Efficiency & speed

With multiple sensors integrated into a single system, different measurement tasks can be performed without the need for manual sensor changes or setups. This saves time and increases productivity.

Vital to every product

From measuring bottle tops to ensure they screw on effectively without leaks, to measuring electronics like smartphones and toys to make sure they fit to specifications, measuring is a vital stage of quality control.

What you can measure:

- Packaging convenience products

- Medical approved products

- Electronics

- Semi-conductors

- Watches

- Toys

- Plus much more

Conquer your measurement challenges

OGP multi-sensor measuring machines are designed to withstand the challenges of everyday measuring. No matter the challenge your team faces, OGP UK experts are on-hand to find the best means of measuring your consumer product.

Get in touch

Get in touch with an expert today. Discover the full power of multi-sensor measurement to save you time and money with your inspection routines.

Improve the consistency and accuracy of your measurements to create better products. Get in touch today to discover more.