In the world of precision manufacturing and engineering, accuracy is everything.

OGP UK stands at the forefront of metrology solutions, offering a diverse range of cutting-edge measurement technologies designed to enhance quality control processes across various industries.

This introduction to OGP UK’s metrology solutions will explore their product range, standout features, capabilities, and the industries they serve.

Product Range

OGP UK provides an extensive portfolio of metrology solutions tailored to meet the evolving needs of modern manufacturing. The product range includes:

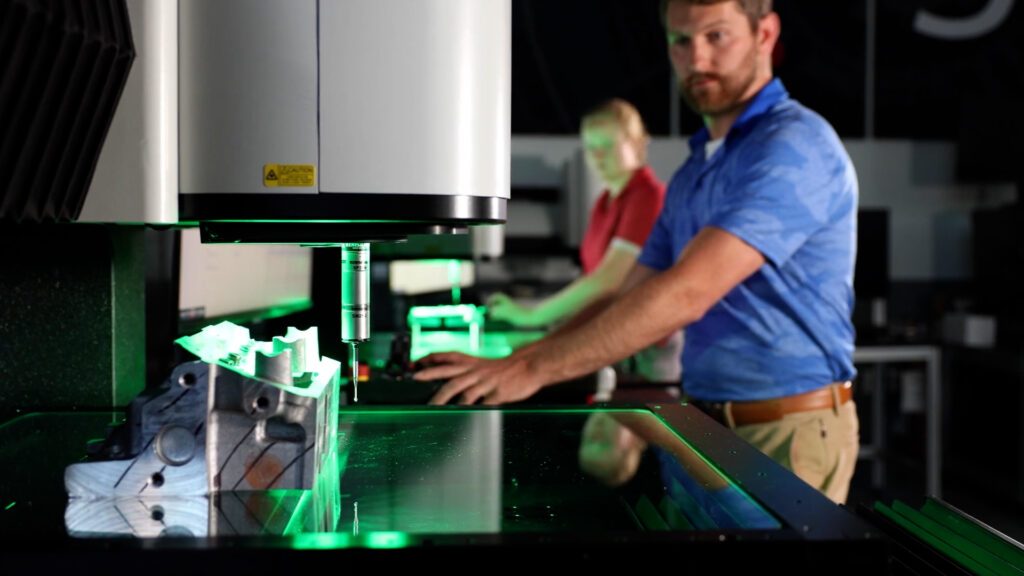

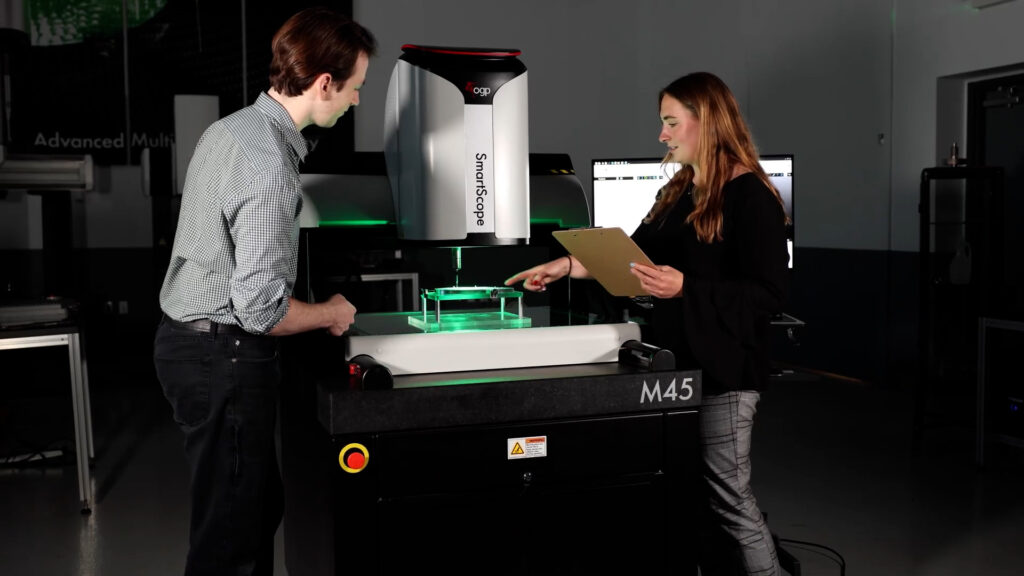

- SmartScope Systems: Multi-sensor measurement systems combining optical, laser and tactile sensors for comprehensive part inspection.

- ZONE3 Software: Intuitive metrology software designed to streamline data collection, analysis and reporting.

- Laser Scanners: High-precision tools for capturing 3D data points quickly and accurately.

- Specialised Solutions: Custom metrology systems developed to solve unique measurement challenges.

Whether you’re inspecting simple components or complex geometries, OGP UK’s solutions ensure precise, reliable measurements every time.

Features

What sets OGP UK’s metrology solutions apart is their combination of innovative technology and user-friendly design. Key features include:

- Multi-Sensor Technology: SmartScope systems integrate multiple sensors to capture comprehensive data in a single set up.

- Automated Measurement Routines: Increase efficiency with programmable measurement routines, reducing human error.

- Advanced Software Integration: ZONE3 software provides real-time data visualisation and detailed reporting.

- High-Speed Scanning: Capture accurate measurements quickly, improving overall productivity.

These features empower manufacturers to streamline quality assurance processes and boost operational efficiency.

Capabilities

OGP UK’s metrology solutions offer an impressive range of capabilities, including:

- Dimensional Measurement: Accurately measure lengths, widths, diameters and angles.

- Geometric Dimensioning and Tolerancing (GD&T): Ensure components meet exact specifications for form, fit and function.

- 3D Scanning: Capture detailed 3D models of parts for reverse engineering or comparative analysis.

- Data Analysis and Reporting: Use ZONE3 software to generate comprehensive measurement reports for quality audits.

No matter the complexity of your measurement requirements, OGP UK provides the tools needed to maintain precision at every stage.

Applications

OGP UK’s metrology solutions are designed for versatility, making them suitable for a wide range of applications. These include:

- First Article Inspection: Verify the accuracy of prototypes and initial production runs.

- In-Process Inspection: Monitor and control quality during manufacturing processes.

- Final Inspection: Ensure finished products meet all specified tolerances before shipment.

- Reverse Engineering: Recreate accurate CAD models from physical parts.

Industries Served

OGP UK works with numerous industries, providing bespoke metrology solutions to address their specific needs. Key sectors served include:

- Aerospace: Ensuring components meet rigorous safety and performance standards.

- Automotive: Supporting precision engineering for engine parts and assemblies.

- Medical: Guaranteeing medical devices adhere to strict regulatory requirements.

- Manufacturing: Enhancing quality control for mass production lines.

Benefits

By choosing OGP UK’s metrology solutions, businesses can unlock a range of benefits:

- Improved Accuracy: Achieve precise measurements for even the most complex parts.

- Enhanced Efficiency: Automate inspection routines to save time and reduce errors.

- Scalability: Solutions adaptable to growing production demands.

- Compliance: Ensure full adherence to industry standards and regulations.

Discover OGP UK’s Metrology Solutions

Ready to elevate your quality control processes? Explore OGP UK’s full range of metrology solutions and discover how their innovative technology can enhance your manufacturing operations.

For more insights on the latest metrology technologies and how it can benefit your business, discuss your challenges with our team today.