Applications now open for:

The Carfulan Group & JCB Academy apprenticeship scheme

The Carfulan Group is pleased to announce that applications are now open for its highly-successful apprenticeship scheme run in partnership with JCB Academy. The scheme offers young people the chance to earn while they learn, taking their first steps into the world of engineering and gaining invaluable real-world experience.

Apprentices will be guaranteed junior role in sales, service, or applications with the Carfulan Group upon the successful completion of a Level 3 Engineering Technician apprenticeship.

Available positions:

Field Service Engineer

The role:

- Three-year specialised programme designed to develop formal engineering knowledge and skills

- Two of those years include spending time at the JCB Academy to acquire a general

engineering certification, with an additional bolt-on year following the

initial training to earn an NVQ qualification - Work will be carried out alongside vastly experienced professionals to provide

knowledge on a wide range of subjects including health and safety,

advanced mathematics, computer-aided design (CAD) software techniques and

machine installation and calibration - Both practical and theoretical methods will be utilised to ensure apprentices

develop the wide range of skills they will need to succeed in the

engineering profession - Apprentices will be required to support customers in real-world scenarios,

establishing new relationships and maintaining existing ones

Course content includes:

- Engineering principles

- Technical mathematics

- Computer-aided design (CAD)

- Mechanical and electrical engineering

Ideal candidates:

- Driven and self-motivated

- Smart and professional

- Friendly and approachable

- Positive and flexible outlook

- Able to work independently and as part of a team

- Good time management skills

- Willing to travel to customer premises with members of staff when necessary

- Good GCSE and/or A-level grades, particularly in science, technology, English and mathematics

- Keen to follow a future career in engineering

What we will offer you:

- A guaranteed junior role in sales, service or applications with the Carfulan Group upon the successful completion of an apprenticeship

- Competitive salary

- Access to personal development training

- Use of a company vehicle when necessary

- Use of a company laptop and mobile phone when required

- Pension scheme with company contribution upon completing an apprenticeship and entering employment

Why choose OGP UK & The Carfulan Group?

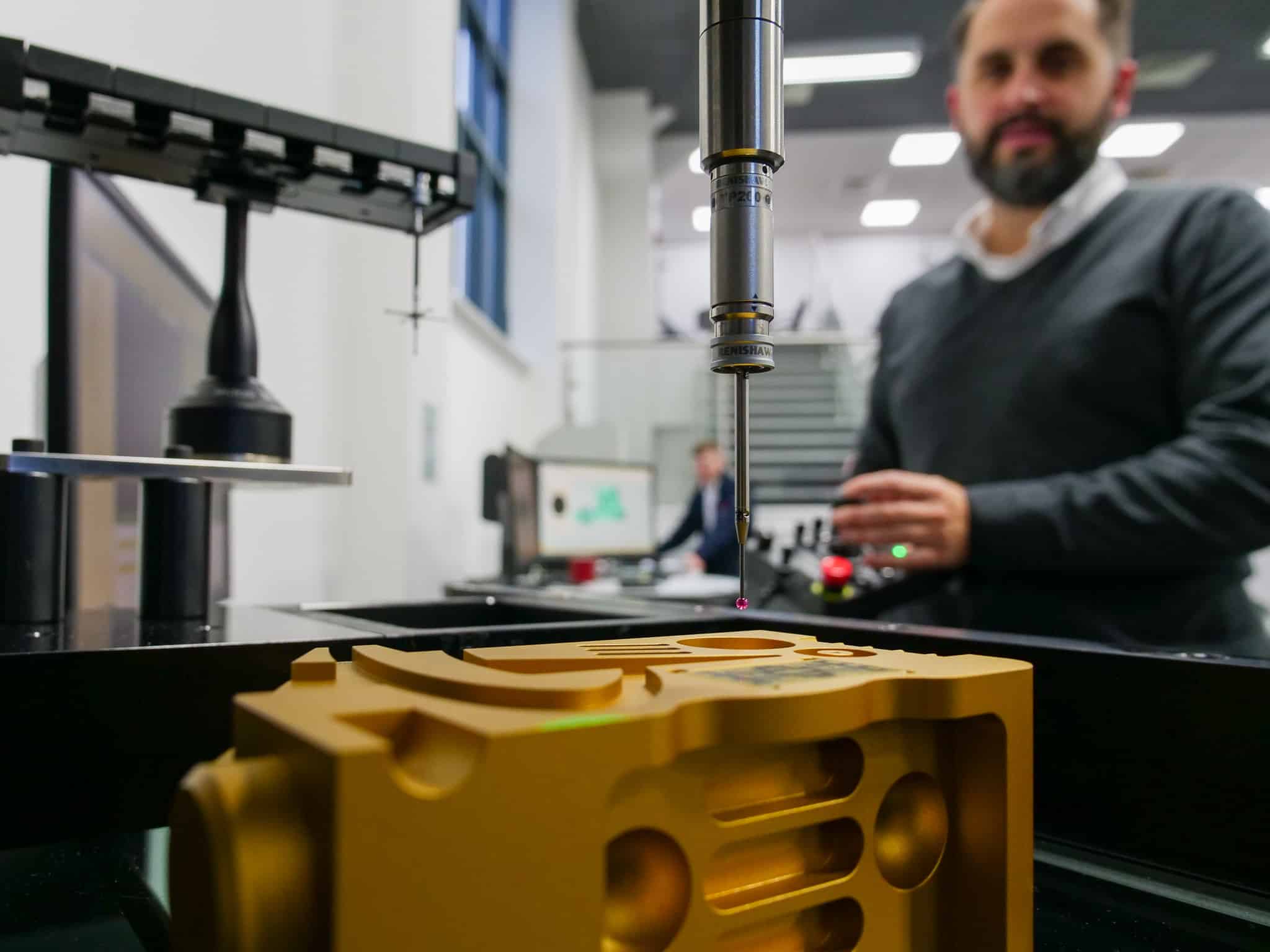

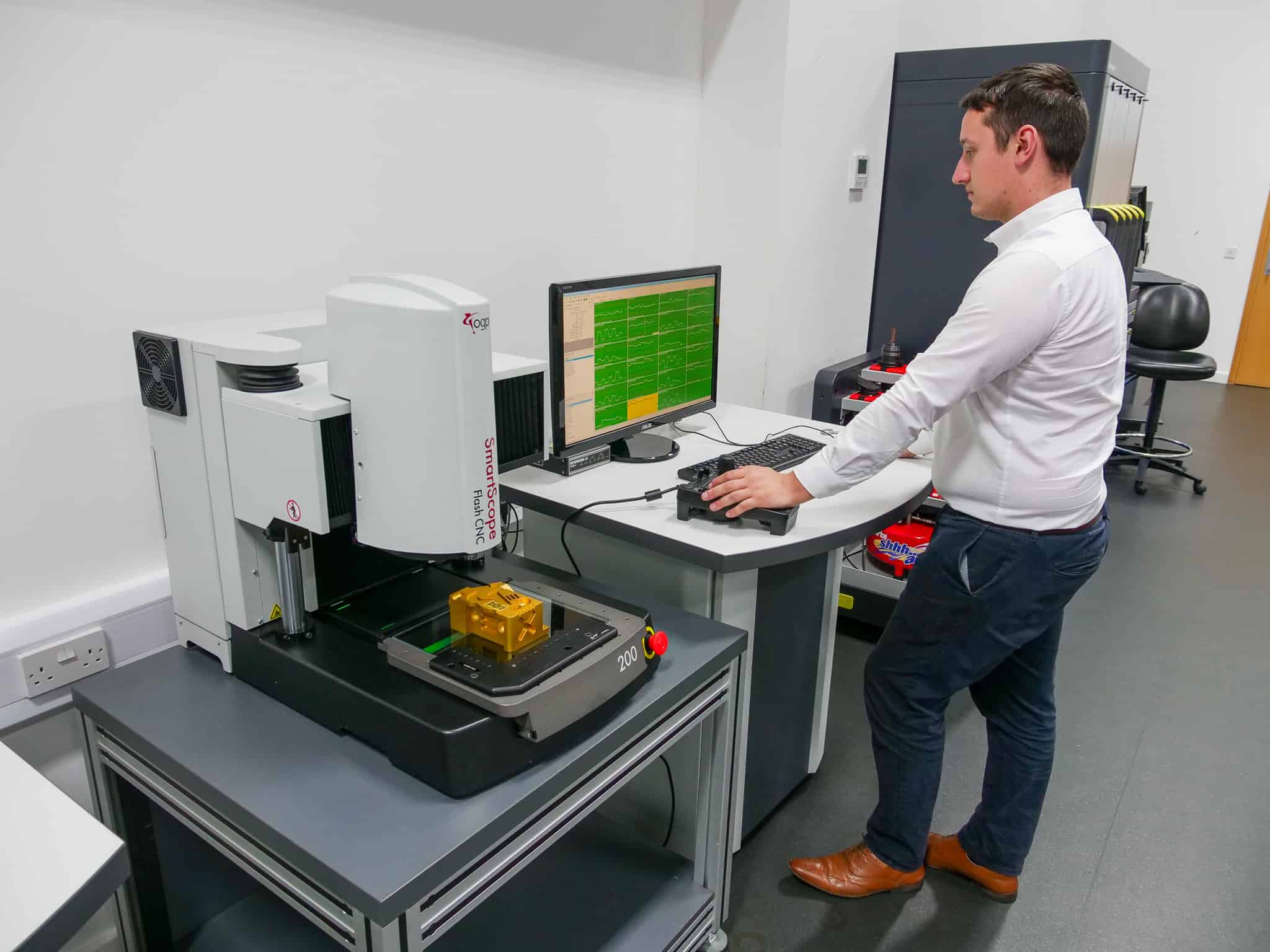

OGP UK specialises in multi-sensor measuring systems for quality control operations in precision engineering, as well as industries including automotive, aerospace, medical, manufacturing and more.

Based in Foston near Derby, OGP is part of the Carfulan group. The Carfulan Group’s most important asset is its people with 80 per cent of the loyal and skilled workforce hailing from the Derbyshire area, offering unrivalled engineering expertise to help businesses improve production performance.

Apply now

Apprentices will be guaranteed junior role in sales, service, or applications with the Carfulan Group upon the successful completion of a Level 3 Engineering Technician apprenticeship.

Closing date for Apprenticeship applications is 4th April 2023. Discover more on Gov website:

https://www.findapprenticeship.service.gov.uk/apprenticeship/1000143884